The Drivers are New.

The Reference Sound Remains.

Few loudspeaker designs hold as much reverence among audiophiles as the classic dual concentric style driver, originally developed some fifty years ago and famously used in Lockwood cabinets throughout the golden age of British studio monitoring. Known for its unique point-source coherence and natural imaging, the dual concentric style driver became a benchmark for critical listening – a reference standard in broadcasting, mastering and high-end HIFI alike.

At Volt Loudspeakers, we’ve embraced the challenge of recreating and refining this iconic design for the modern era. Working closely with Lockwood, we’ve developed a new range of drivers that honours the sonic heritage of the original whilst incorporating decades of our own engineering expertise and innovation. This isn’t a replica – it’s a respectful evolution.

We hope you enjoy the gallery below which takes you inside the process: from the redesign of the chassis, the change in surround material and of course the ‘pepper pot’ waveguide.

All handcrafted here in Dorset.

Chassis

The cast aluminium chassis has been completely re-engineered to deliver both improved aesthetics and function. The outer raised lip has been removed, allowing the newly designed surround to sit flush within the recess—eliminating the need for a gasket. Where Tannoy originally used mechanical fixings to bolt down the suspension and gasket, we’ve transitioned to advanced aerospace-grade adhesives, making bolt holes obsolete and improving rigidity. Each chassis is lightly hand-sanded to remove micro-imperfections as part of our rigorous quality control process.

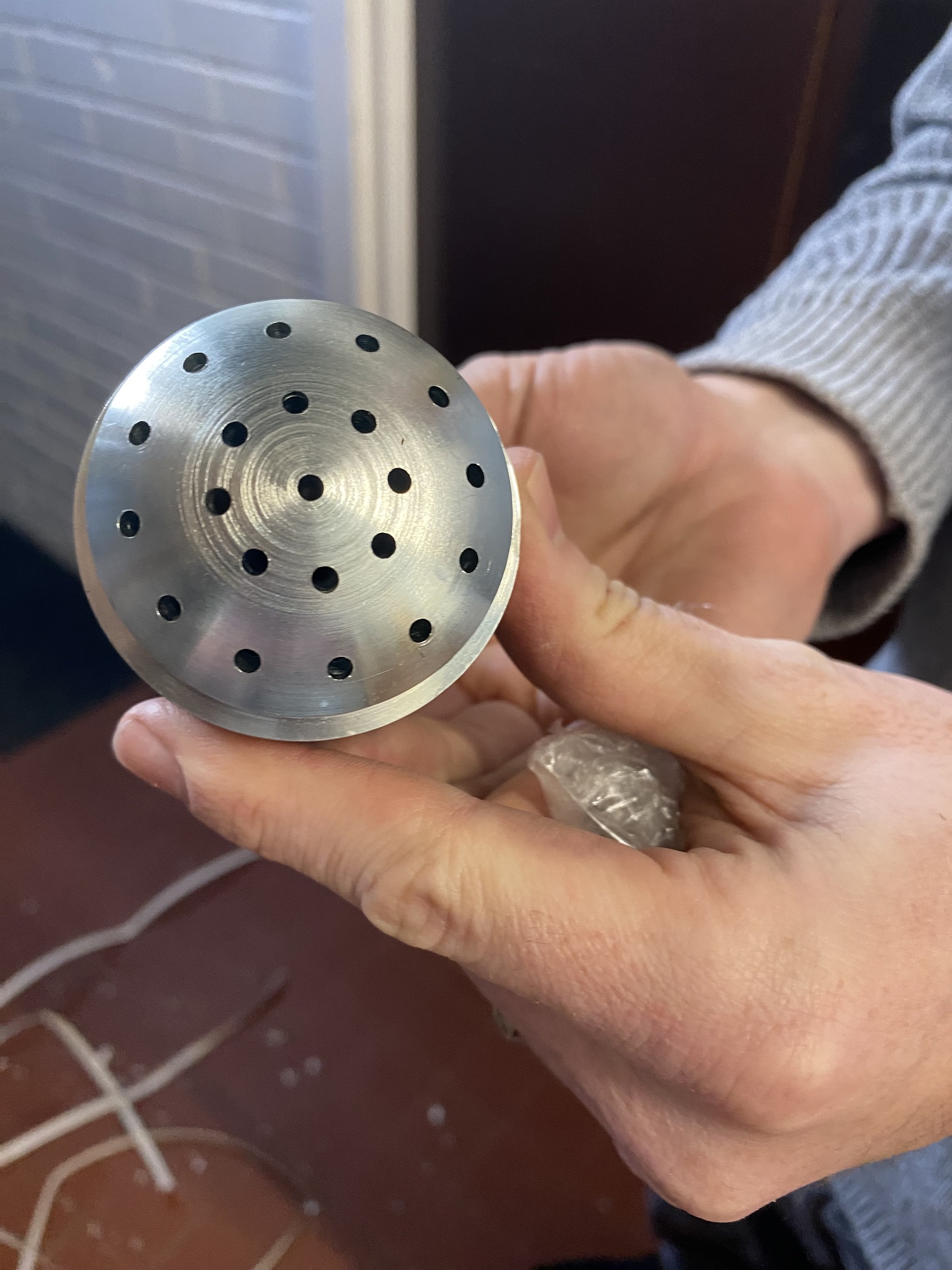

'Pepper Pot’ Waveguide

An iconic element of the original design, the so-called ‘Pepper Pot’ waveguide plays a critical role in the high-frequency performance of the driver. In our updated version, the perforations are now precision-machined for consistency, ensuring optimal wave propagation from the waveguide into the horn throat. This meticulous attention to detail helps preserve the smooth and coherent response the originals were known for.

Magnet Assembly

Lockwood Loudspeakers continue to use alnico magnets. Alnico is key to delivering the musicality and tonal character these drivers are celebrated for, and its use remains non-negotiable. The LF section retains its aluminium shorting ring, while we’ve added a new one to the HF motor to further reduce harmonic distortion and improve overall performance.

Paint Finish

The chassis was originally painted gold, though it was never visible due to the gasket. With Lockwood’s updated design, the outer radius is now visible, so we’ve treated the chassis to a full application of a two-part, dead matte black paint. The resulting finish has a soft, suede-like texture that complements the rubber surround and contributes to the speaker’s understated, high-end aesthetic.

Cone

The cone geometry remains faithful to the original specification, preserving its sonic signature. We still use a paper pulp cone, but with a more modern formulation that’s resistant to discolouration over time. Additionally, the rear surface and outer edge of each cone are specially treated—this not only enhances high-frequency response but also prevents edge delamination, ensuring long-term durability.

Surround

While the original units used foam surrounds, we’ve developed custom tooling to produce a new rubber surround with a half-roll profile. This modern material offers superior longevity and stability, especially at low frequencies. It also visually complements the rest of the driver, bringing together form and function in a way that suits the updated Lockwood aesthetic.