Radial

Technology

Committed to innovative engineering, Volt Loudspeakers actively handle power compression through patented Radial Technology.

A Unique Chassis Design

Radial Technology is based on a unique chassis design which, unlike conventional loudspeakers, is fitted to the heart of the magnet and is outside the enclosure in cool air, creating a massive heatsink. Heat is transferred away from the voice coil and magnet assembly so our speakers run cooler, giving you optimal sound quality, however long you listen.

Still the world's coolest loudspeaker...

Benefits of using Radial Technology

At working power levels Radial loudspeakers will run at half the temperature of conventional speakers. Consequently when things begin to heat up, the power and definition of Volt Radials will remain consistent and will be running twice as loud as a conventional speaker that started a session at the same time. Subsequently, half the amount of Radial drive units will need to be used compared with conventional drive units doing the same job.

Radial Technology defines reliability and performance

The genuinely cooler operation improves bass response by maintaining the correct relationship between the loudspeaker and the enclosure. It maintains the correct midband output at higher power levels which preserves overall system balance. Whether that’s to withstand the demands of a studio environment or to ensure the longevity and quality listening experience of a high-end hi-fi system. Volt’s Radials are an intelligent investment.

How does Radial Technology work?

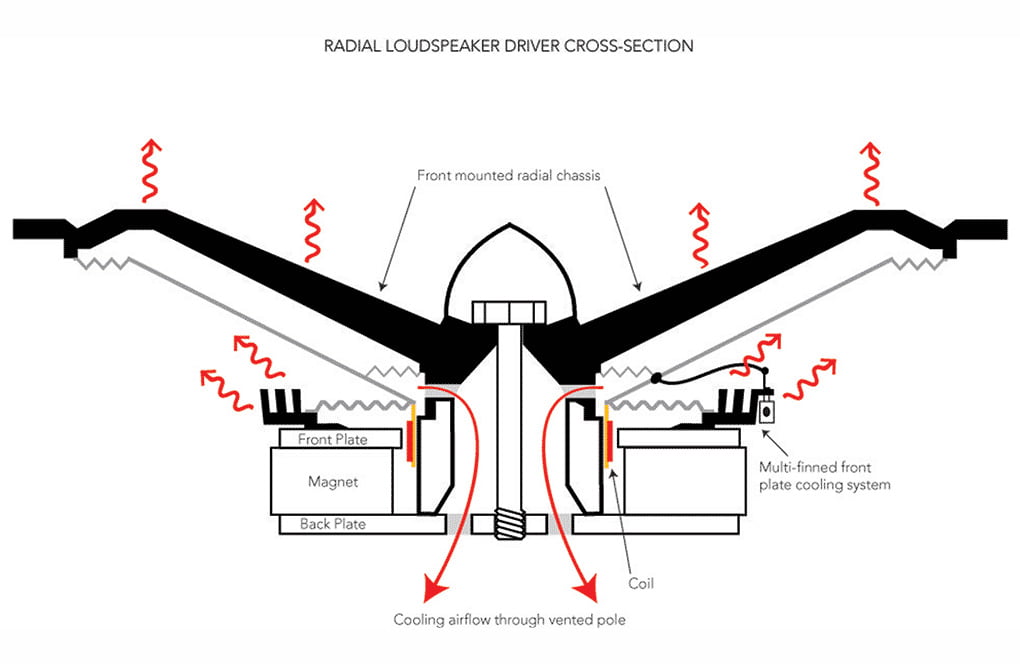

The speaker chassis sits in front of the cone and is mounted to the centre of the magnet system through the voice coil. The chassis is in cool air at all times and thus draws heat from the coil whilst cone movement enhances airflow past the chassis legs. The chassis is acting as a massive heatsink and dissipates heat outside the cabinet. This chassis is bolted to the centre pole of the magnet and due to its heatsink function, the magnet system also stays cool which further protects the voice coil from unwanted heat. In addition, Volt incorporate a multi finned front plate cooling system that not only disperses heat but allows air to flow behind the rear suspensions and over the voice coil. The combination of these features working on top of a vented magnet means cooler running and improved performance and reliability.

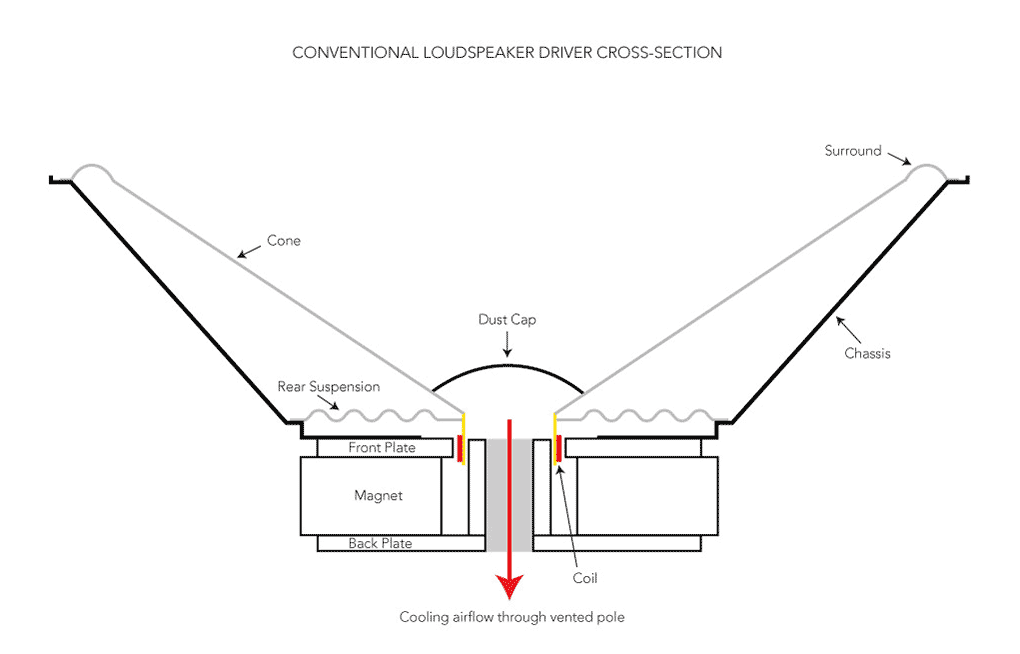

In a conventional unit, hot air is pumped through a vent in the magnet into the cabinet. As this is the only cooling system, the voice coil will quickly heat up and a reduction in performance will soon become obvious.

“The new frame radiates almost twice the heat into the ambient air, which makes it much more reliable in high power applications. The improved thermal conductivity between voice coil and magnet structure also reduces power compression for long term signals with excitation times of more than 3 seconds.”

Dr G. Behler

Technically Speaking

Heat and Loudspeakers

Cone loudspeakers are very inefficient, with even the best transducers only converting around 5% of the electrical energy supplied into sound, the rest is converted into heat in the voice coil. The wire used in voice coils has a property that it shares with resistance wire used in domestic appliances such as electric heaters, toasters, etc. As the wire gets hotter its resistance increases. In this type of appliance the increase in resistance with temperature is designed to limit power to a safe operating level. However this power limiting feature is undesirable in loudspeakers because output should not be limited by the voice coil temperature. Unfortunately, this is a drawback of all moving coil loudspeakers.

How does voice coil resistance work

Consider two identical loudspeakers, one is 8 ohms and the other 16 ohms, connected to identical amplifiers with the same input and volume at the same setting. The 16 ohm speaker will draw half the power of the 8 ohm speaker because its voice coil has twice the resistance. It will produce half the power output and a sound level meter will show this as being 3dB less. In other words higher voice coil resistance means lower power drawn and thus lower acoustic output. Over the years loudspeaker adhesives have advanced, and a modern state of the art voice coil is designed to withstand extremely high temperatures operating at up to 300°C when driven hard. At only 230°C the voice coil resistance has actually doubled. In any loudspeaker used close to its rated power handling 230°C can easily be reached. Some simple maths and you can quickly see that the increase in temperature can make your 8 ohm speaker behave like a 16 ohm speaker, which will cause it to draw half the power it did when it was cold. The result is known as power compression. The example above describes 3db power compression.

Power Compression

Power compression is the little bugbear that can upset your best laid plans, and give you reason to throw the manufacturer’s specifications out the window. Many manufacturers choose to ignore power compression, some actively avoid specifying it or even mentioning it. Power compression will cause the volume to drop, and if you have sufficient voltage headroom in your amplifier system, you may be tempted to turn your amps up, whilst this may initially give you a slight increase in volume, ultimately it will just cause more heat to be produced, and even more power compression – ultimately leading to costly driver failure. Apart from the loss of output level, power compression also has a noticeable negative effect on sound quality, common symptoms being suppression of the mid output and misaligned bass enclosure tuning, resulting in boomy bass and muffled mids.

Radial Technology

Volt have taken an innovative approach; actively tackling power compression. The result is Radial Technology – a patented cooling concept based around a unique chassis design. Radial Technology defines reliability and performance, whether to withstand the demands of a studio environment or maintain quality and power in PA applications, savings made in hardware, installation and repairs make Volt’s Radials the intelligent investment.

"Volt's Radial Technology solves the problem of power compression that is exacerbated by the build-up of heat in an enclosure."

Vance Dickason

Editor of Voice Coil

Where is it used?

Radial Technology works! It’s no coincidence that this cooling system can be found in speakers systems used in many of the planets most prestigious locations; Abbey Road Studios and BBC’s Maida Vale at home in the UK and by Academy Award winning Composer Hans Zimmer in the US. Radial Technology is used in the larger models in both our studio and Pro PA range where power handling is a priority; browse our product range for a closer look. Volt Loudspeakers are also experienced in building bespoke drive units that use Radial Technology for OEM customers who have specific design requirements. We supply PMC, for example, with our patented Radial chassis as part of PMC’s 12″ and 15″ LF units that are used in both the most rigorous and critical professional environments and in the world’s most respected audiophile designs. Contact us if Volt can be of assistance in a similar way.

“ I have to conclude that the concept works extremely well and it does indeed produce the benefits claimed.”

Ken Dibble

Sound & Communications Magazine